Master Electrical Load Listing: Step-by-Step Design Guide | AmperePro

Learn the professional methodology for electrical load estimation. Master diversity factors, demand factors, and international standards (IEC/IEEE)

The Essential Guide to Electrical Load Listing: Standards, Methodology, and Best Practices

Introduction:

In the world of electrical engineering, the Electrical Load List (ELL) is the heartbeat of any project. Whether you are designing a high-rise commercial complex or a sprawling industrial plant, the accuracy of your load list dictates the sizing of every component—from transformers and generators to cables and switchgear.

A mistake in load estimation doesn't just lead to inefficient power usage; it can lead to catastrophic equipment failure or massive unnecessary CAPEX (Capital Expenditure).

In this guide, we break down the fundamentals, the standards, and the step-by-step methodology for creating a professional-grade load list.

Fundamentals of Electrical Load Listing

695f83b722d97_lg.jpeg)

What is the Purpose of a Load List?

The load list is a living document that captures the power requirements of all electrical consumers within a system. Its primary goals are:

- System Sizing: Determining the capacity of the main power source (Utility/Transformers).

- Redundancy Planning: Sizing backup power like UPS and Emergency Generators.

- Cost Optimization: Avoiding "over-designing," which wastes money on oversized equipment.

Types of Electrical Loads

In both buildings and industries, loads are typically categorized to help in calculation:

- Continuous Loads: Operates for 3 hours or more (e.g., lighting, HVAC).

- Intermittent/Non-Continuous Loads: Operates periodically (e.g., small power tools, pumps).

- Standby Loads: Used only during emergencies (e.g., fire pumps).

Expert Tip: Always separate "Essential" loads from "non-essential" loads. This is critical for designing your load shedding logic during power failures.

Standa9rds and Design Considerations

Engineering is nothing without compliance. Following international and local standards ensures safety and global interoperability.

Applicable Standards

- IEC 60364: The international standard for electrical installations in buildings.

- IEEE 399: Known as the "Brown Book," it provides the gold standard for industrial and commercial power system analysis.

- IS (Indian Standards) 732: Crucial for projects adhering to regional safety codes in India.

Engineering Safety Margins

Standard practice suggests a Future Growth Margin (typically 10% to 20%) should be added to the total calculated load. This ensures the infrastructure can handle future expansions without requiring a total overhaul of the switchyard.

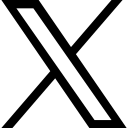

Load Estimation Methodology

Calculating the final load is more than just adding up the numbers on the motor nameplates. It requires the application of Diversity and Demand factors.

Step 1: Identification and Grouping

Group your loads by their functional area (e.g., Utility, Process, HVAC, Lighting). This allows for easier troubleshooting and more accurate diversity application.

Step 2: Connected Load vs. Peak Demand

- Connected Load: The sum of the continuous ratings of all equipment.

- Demand Factor: The ratio of the maximum demand of a system to the total connected load.

Max Demand = Connect Load X Demand Factor

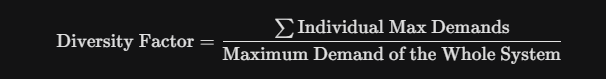

Step 3: Applying Diversity Factors

In a large facility, not every machine runs at full capacity at the exact same second. We apply a Diversity Factor to account for this.

Note: The Diversity Factor is always > 1.

Practical Application and Common Pitfalls

695f84266c4da_lg.jpeg)

Preparation of the Final Load Schedule

A professional load schedule should be presented in a table (usually Excel) containing:

- Tag Number/Description

- Rated Power (kW/kVA)

- Efficiency and Power Factor

- Operating Mode (Continuous/Intermittent/Standby)

- Calculated Absorbed Power

Common Errors to Avoid

- Ignoring Power Factor: Always calculate based on kVA, not just kW, to account for reactive power.

- Double-Counting Standby Loads: Never add the fire pump load and the main process load together if they are never intended to run simultaneously.

- Neglecting Voltage Drop: An accurate load list is the first step in performing a voltage drop analysis to ensure equipment receives its rated voltage.

Conclusion: Accuracy Drives Efficiency

A well-engineered Electrical Load List is the difference between a system that is "just functional" and one that is "optimized." By following IEC/IEEE standards and applying rigorous diversity factors, you protect your project from both safety risks and budget overruns.

Take Your Design to the Next Level

Are you currently working on a power system design? Having the right tools makes all the difference.

The Mastering Electrical Design Calculations Course by Ampere Pro Engineers is specifically designed to bridge this gap. Led by Mr. Jeyakumar Velusamy (16+ years of Oil & Gas experience), this bundle covers 25 specialized modules—from busbar sizing to hazardous area classification.

Categories: : Calculations, Career Growth, Electrical Masterclass, IEC Standards, Load List Calculation

Jeyakumar Velusamy

Jeyakumar Velusamy